How does a water pressure booster pump work?

Water pressure is something most homeowners don’t even think of, until it is not there! It is the difference between an average and great shower or being able to water your entire garden effectively through your irrigation system.

Then there is also the need to transfer water from one point to another to be useful. Perhaps you harvest rainwater in a tank for your garden; your municipality’s infrastructure is neglected; or you rely on a borehole and/or reservoir on an elevated stand to supply your home with running water. But how to get this water from point A to B?

Luckily there is a product that can help – water pressure pumps! In this article we explore how does water booster pressure pumps work, and what they can be used for.

The ideal water pressure for a refreshing shower or to hose down your bakkie is between 2,5 and 3,5 bar (36 to 50 psi). Unfortunately, due to a variety of factors we don’t always have this kind of pressure in our water pipes.

To give an idea of how significant this pressure requirement is, if you have a water tank ten metres off the ground, this gravity system will give you 1 bar of pressure when all the outlets / taps are closed. This pressure will reduce significantly as soon as an outlet is opened. This is where a water booster pressure pump can greatly improve the water pressure throughout the whole system.

How does a water pressure booster pump work?

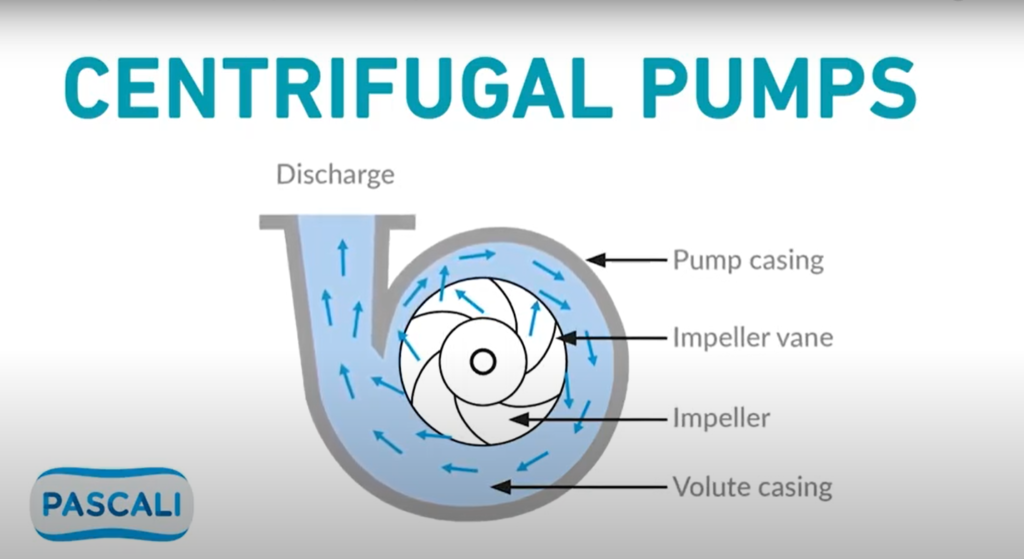

A water booster pressure pump is basically a specially designed and manufactured electric fan that uses an impeller to move water along pipes.

Different types of pressure pumps have different impeller designs with different characteristics. All pressure pumps however have an inlet from the water source – usually a tank or reservoir – an outlet that goes to your house or garden, and a sensing device to switch the pump on and off according to preset parameters. This sensing device can be either electronic – measuring the flow of water, or mechanical – measuring the pressure.

The importance of pressure and flow

Flow and pressure are two sides of the same coin. As flow increases, pressure decreases. A pressure tank is often added to the system to provide a reserve of pressurised water, this prevents the pump from kicking in every single time someone opens a tap for smaller quantities of water, like washing hands or filling a glass of water. This extends the life of the pump, reduces wear-and-tear, and prevents needless power consumption.

Water consuming appliances such as washing machines, dishwashers and icemakers also require a minimum water pressure to function correctly. These machines have their own valves to regulate the water flow and often rely on steady, predictable pressure to function correctly. A major washing machine manufacturer recommends that the water pressure shouldn’t be below 1,4 bar (20 psi). Water pressure lower than 1,4 bar can reportedly cause a water valve failure or prevent the water valve from shutting off completely. There is also a fill time limit built into the controls of most washing machines and if the machine doesn’t receive the predetermined amount of water, the wash cycle won’t live up to your expectations.

Remember that to achieve 1,4 bar of pressure with gravity alone will require a tank stand more than 14 metres high!

So in short: A water pressure booster pump pushes water at a faster rate and at a higher pressure than the existing pressure, and switches off automatically when no water is used.

All Pascali’s pumps and motors have stainless steel motor shafts, 100% copper windings, brass impellers and cast-iron or stainless-steel pump bodies to provide many years of hassle-free service.

Hear from our technical expert on this very subject on the informative video below;